Mixing is an important step in cosmetics production. Operations include dissolving solid powders, preparing emulsions, performing chemical reactions, and more. During the mixing process, efficiency and accuracy are key to ensuring dosing accuracy, stability, appearance and texture.

The lifting vacuum emulsifier is specially designed for the cosmetics industry to produce products with high viscosity and high emulsification requirements. The biggest features of this cosmetic machine are:

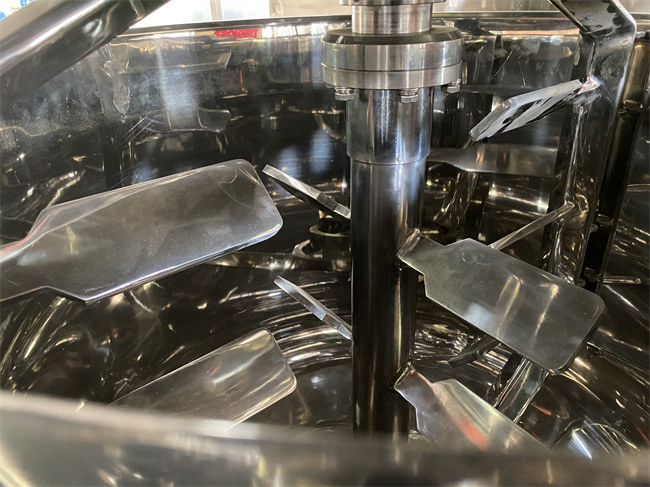

1. The materials are continuously emulsified in the circulation

2. Emulsify high-viscosity materials more thoroughly without dead ends

3. The external circulation emulsifier can be discharged instead of the delivery pump and can be circulated for cleaning. The makeup machine adopts front and back double scraping edges and a high-speed external circulation emulsifying head design

About the cosmetic machine cover

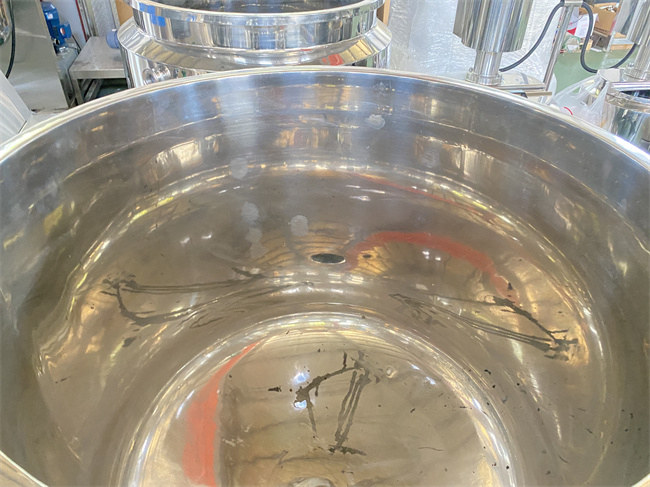

The unloading and cleaning of the cosmetic machine mixer adopts a hydraulic lifting system, which is simple and convenient to operate.

Cosmetic Machine Working principle:

After the materials are heated, stirred and reacted in the water pot or oil pot, they are sucked into the emulsification pot by the vacuum pump, and stirred through the upper center of the emulsification pot, so that the captured materials continuously create new interfaces, and then are cut by blades and rotating blades. , compress, fold, stir and mix, then flow downward to the homogenizer under the pot. In the process of strong shear, impact, turbulence, etc. between the grinding wheel and the fixed shear sleeve. The material is sheared in the shearing gap and quickly broken into particles of 200nm-2um. Since the emulsification pot is in a vacuum state, the bubbles generated during the stirring process of the material are removed in time.

If you want to know more questions, please feel free to contact us!