1. Improve production efficiency : Per hour capacity 100 - 300kg!

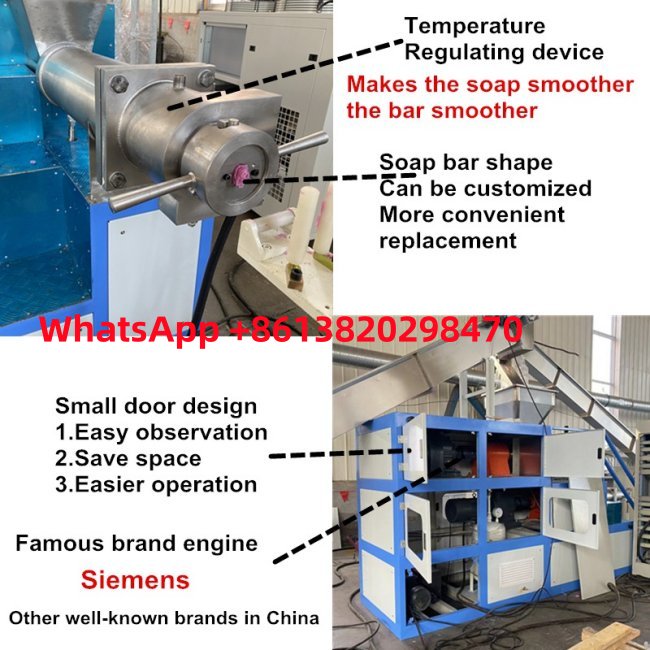

2. Ensure stable product quality : Soap more beautiful,firmer and delicate!

3. Save labor costs : only 6-8 people are needed for each production line!

4. Reduce production costs : Less material waste , less power , fewer people!

Most important : Fast Capture the market !

1.Materials: soap noodle (soap grains), pigment, fragrance.

2.Workshop: above 75 m2, L: 15 m, W: 5 m, H: 3.5 m, including operating space, excluding packing machine.

3.Power: 25 kW, 380 V, 50 HZ.

4.Staff: 6 ~ 8 persons.

Choose the domestic famous brand hard gear reducer, long service life!

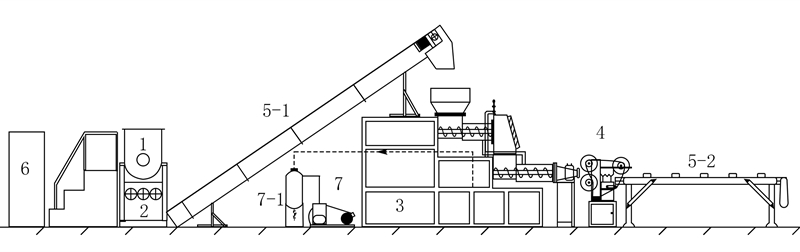

Type : JHYF - 50

Capacity : 50kg/batch

Mix time : 5 miuture

It is used to make the soap particles and additives mixed more evenly, the soap body structure is tight, and

the density and quality of the soap body are improved!

Type : JHYF - S150

Roll diameter : Φ150 mm

Roll face length: 300 mm

The soap base was extruded and refined to make the soap bar compact in structure and smooth in surface.

Type : JHYF - 300

Capacity : 100 -300 kg /hour

Screw outside diameter : Φ160 mm

Motor power : 4 +5.5 kw

JHY AUTOMATIC MACHINE company has an independent office area, production workshop and finished product

line debugging workshop! Professional production technical personnel 20+ , Senior instruction technician 5+

Professional marketing production team at your service!

Product warranty for three years! (Except for human improper operation.)

Technical guidance: We provide free production formula, process technical guidance to ensure the production of

qualified products. Full spare replacement within the warranty period and at the factory cost after that.