Filling products: filling of hand sanitizer, antibacterial liquid, liquid soap, detergent and other viscous liquids.

The new filling machines we have developed have reached the international advanced level, and some have surpassed similar products. Our filling machine is a piston cylinder, PLC programming control, and touch screen control.

Our advantages: accurate measurement, advanced structure, smooth operation, low noise, large adjustment range, fast filling speed, etc.

It is also suitable for liquids that are easy to evaporate and foam. The operator can adjust the metering numbers on the touch screen control panel and can also adjust the metering of each filling head. The exterior is made of stainless steel and is durable!

1.Specially designed thickened sealing ring, no replacement required within 3 years

2.SUS316 material filling head

3.SUS304 frame, 5mm thick 316 graduated cylinder

4. Each valve and filling head is equipped with a detector. If there is a problem with any filling head, the touch screen will display it, making it easy to check the problem.

5.With cleaning system

6. Equipped with 316L stainless steel rotary valve, suitable for filling viscous liquids

| Filling Head | 6 |

| Filling Capacity (1L) | 1800B/H |

| Power | 3Kw |

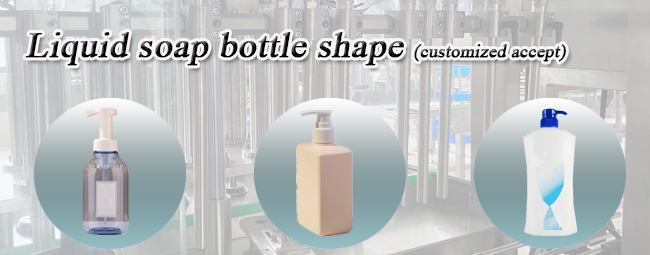

| Suitable Bottle |

Round Bottle Height : 100 - 320mm Diameter : Φ 60 -140mm Flat Bottle Length : 100 - 200mm Width : 40- 80mm Height :150-300mm Neck Diameter : ≤Φ 30mm , also can be customized |

| Filling Range | 50 - 1000 ml |

| Power Supply | 380V , 220V all accept |

Vacuum homogenizing emulsifier

It mainly refers to the use of a high-shear emulsifier to quickly and evenly distribute one phase or multiple phases into another continuous phase when the material is in a vacuum state. It uses the strong kinetic energy brought by the machine to make the material pass through the narrow gap between the stator and the rotor. medium, withstanding hundreds of thousands of hydraulic shears per minute. The comprehensive effects of centrifugal extrusion, impact, tearing, etc. instantly disperse and emulsify evenly. After high-frequency cycles, a bubble-free, delicate and stable high-quality product is finally obtained.

After-sales service:

1. Provide professional operation manual

2.24 hours online support

3.Video technical support

4. Free spare parts are provided during the warranty period

5. On-site installation, commissioning and training

6. On-site maintenance and repair services