|

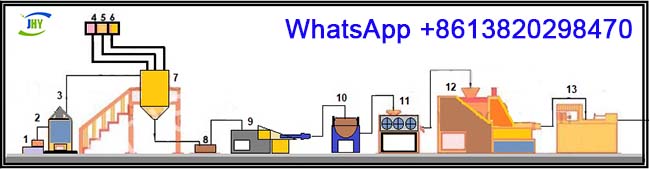

Laundry or Toilet soap making production Line of 1000 kg per hour production capacity. |

Introduction:

This production line is a laundry soap making complete line

starting from caustic soda melting, saponification, vacuum

drying and cooling, milling soap noodles, vacuum extruding

and then stamping & cutting into soaps, till packing.

|

Advantages at a glance. 1. The most advanced technology 2. Fully automatic 3. covering less floor area 4. consuming less energy 5. saving human resources |

The soap making production line consists of

units from saponification to soap bars.

A. Saponification Cauldron

|

It is the start of the soap making process. Saponification is done between oil and Caustic Lye. |

1. Sufficient reaction. 2. Saves water. 3. Comes with heating pipe liner and blender 4. Attached frequency conversion motor. |

B. Pelletizer

|

It is used to press the vacuum-dried soap materials into soap noodles. |

1. Produces the finest soap noodles 2. Semi finished soap 3. Ready for sale as soap raw material |

C. Mixer/Agitator

|

Soap noodles and other additives are mixed efficiently. |

1. Sigma mixing 2. Capacity: 100 kg/batch; 3. Mixing time: 5-10 min; |

D. Three-roll-mill

|

Three-Roll Grinding Mill is used to grind, press the material to improve its density and quality. |

1. Oil-sink type 2. Low noise 3. Long life span |

E. Vacuum Plodder

|

Vacuum Plodder is used to grind, refine and press soap material into soap bar. The above and below screws and two orifice plates press and refine the soap material and make the soap bar tight and the surface bright. |

1. Adopt hard-teeth reduction gear Attached with frequency conversion motor |

F. Cutting and Stamping Machine

|

It is used to cut soaps into cakes and stamp patterns on the soap. |

1. Adopt two sets of Yaskawa servo motor 2. Keeps high accuracy 3. The mould wheels run by the moving of soap bar from vacuum plodder 4. Can cut soap bars with any sizes and weight after setting the computer. |

G. Film Packing machine

|

The packaging machine is used to pack toilet soap, laundry soap, and other regular shape products. |

1. Simple structure 2. Less wear and long-life span. 3. Can adjust the bags’ size and speed automatically 4. Sealing temperature is controlled separately 5. Sealing is tight and beautiful The tracking system cuts the bags accurately after set-up. |

The greatest advantage of the soap making production line:

|

It is a turn-key project. The professional team provide you all machines and accessories, formula, layout design, machines installation, products trial -- all solution according to your requirements. |