Soap making machine automatic offers a comprehensive solution for modern soap manufacturers, combining efficiency, precision, and flexibility. Elevate your production capabilities and stay ahead in the competitive soap market with the advantages provided by our state-of-the-art automated systems.

1. Raw materials: soap granules, essence, pigment, talc powder, etc.

2. Circulating cooling water: 1 cubic;

3. Electricity: 40-50 kW/h, 380 volts, 50 Hz;

4. Workshop: 20 meters long, 5 meters wide, 3.5 meters high, excluding packaging area;

5. Labor: 6 people/class.

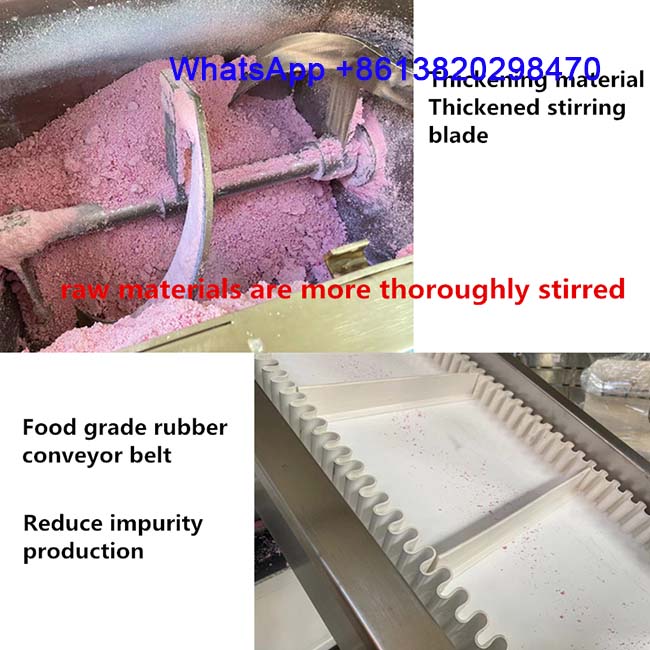

The mixing machine is to mix various additives and soap grains for the production of soap to meet the requirements of the formula. The use of domestic well-known hard gear reducer, low noise, long life.

Type : JHY - 100

Capacity : 100 kg /batch

Mixing time : 5-10 minutes

It is used to make the soap particles and additives mixed more evenly, the soap body structure is tight, and the density and quality of the soap body are improved.

Type : S260

Roll diameter : Φ260 mm

Length of roll face : 780 mm

Roller speed ratio : 1 :3 :9

Grind size : 0.05MM

The vacuum stripping machine is a soap making equipment for refining, venting and extruding the ground soap base into soap bars. The soap base is extruded and refined by two screws and two layers of holes on the drawing machine, so that the soap bar has tight structure and smooth surface.

Adopt the domestic well-known brand hard gear reducer, and the lower outlet is the variable frequency speed regulating motor.

Type : JHY - 500

Capacity : 500 -800 kg /hour

Screw outside diameter : Φ200 mm

Package : stretch film packaging

Load : 20'fcl or 40'gp container

Delivery time : About 35 -50 days after received the deposit !

1.Quality Assurance:

Ensure high-quality soap products with built-in quality control features. The machinery is equipped with sensors and monitoring systems to detect and address any deviations from the desired quality standards during the production process.

2.Customization Options:

Tailor your soap products to meet specific market demands. Our machinery supports customization options, allowing for the incorporation of various scents, colors, and additives to create a diverse range of soap variants.

3.User-Friendly Interface:

Simplify operation with an intuitive and user-friendly interface. Operators can easily control and monitor the entire production process, making adjustments as needed to maintain efficiency and quality.